Enabling Manufacturing &

Supply Chain Resilience

Locations

Head Office

- JAF Solutions, Level 25, 108 St Georges Terrace, Perth, Western Australia

6000 - [email protected]

- +61 8 6557 8947

Welcome to JAF Solutions

Having good visibility and the agility to shift sourcing, manufacturing and distribution activities around fairly rapidly will help ensure your resilience. Disruption of traditional business models is occurring on several fronts in many industries. Technology is a key enabler to navigating these disruptions.

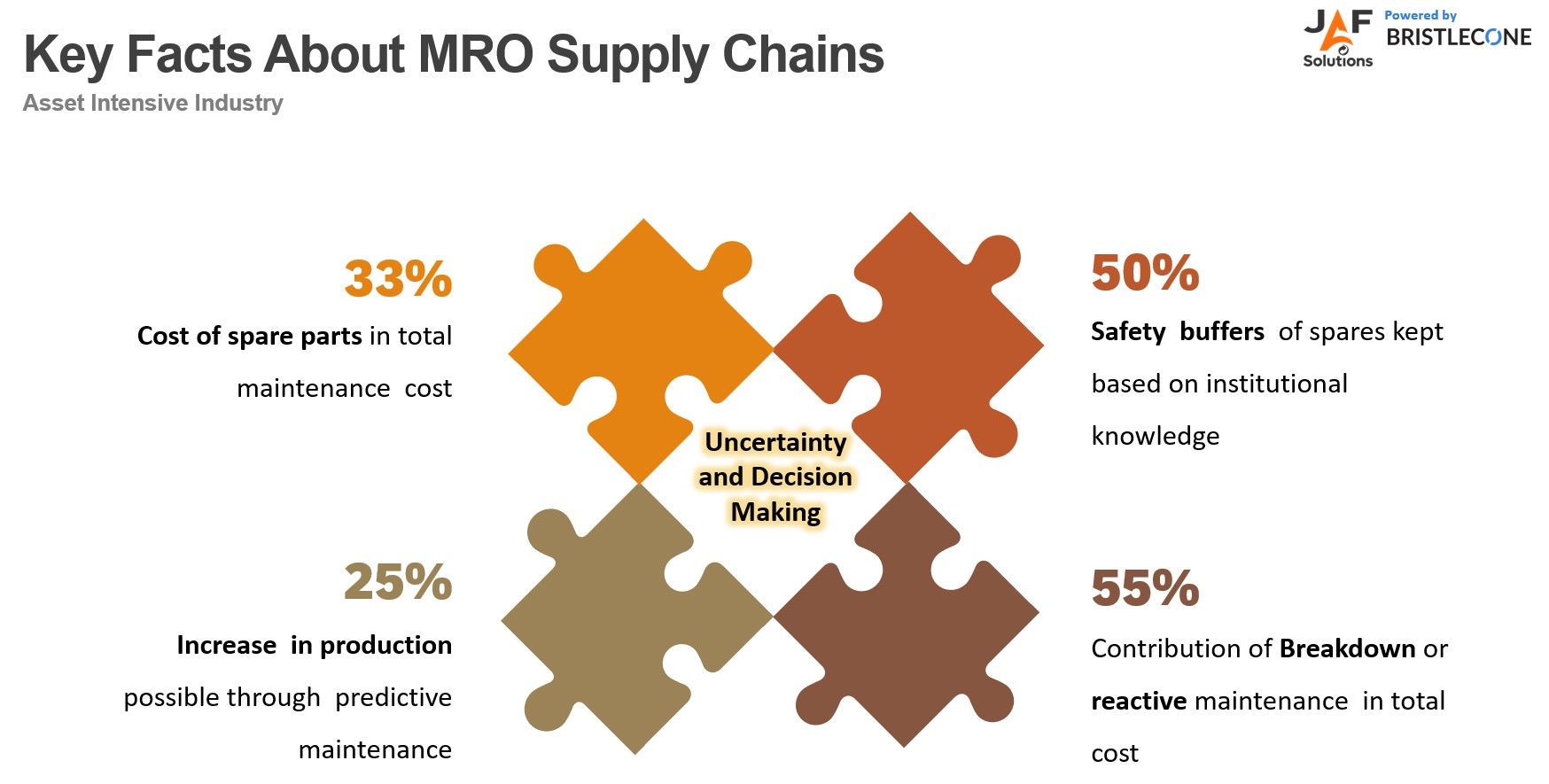

Asset Intensive Industries are not immune to these disruptions as they are experiencing supply chain disruptions affecting cash and profits. ESG requirements and sustainability introduces process and regulatory standards adding further social license to operate pressure on resource industry to adapt and improve. Notwithstanding these recently emerging challenges, the industry must also maintain effort in safely optimizing production.

Recent world events have exposed several vulnerabilities in the mining industry, including the risk inherent in long supply chains. The move to partner with Original Equipment Manufacturers (OEMs) is evolving the traditional business-to-business model to a direct one of business-to-consumer one.

The decision last year to bring suppliers closer to mine operations is continuing and is helping to work toward securing reliable access to goods and services. PWC Global Mine Report 2022 identifies emerging trend of OEMs and end users partnering directly within mining. The Top 40 miners are evaluating opportunities to own more of the supply chain and to partner directly with OEMs and local suppliers.

Some of those Top 40 are looking at other ways to build supply chain resilience. For example, BHP is using advanced analytics to create visibility across multiple tiers of its supply chains in real time.

The company can see and respond quickly to disruptions across suppliers, extending to tier-two suppliers and beyond.

BHP also shares its data with key suppliers, making the entire supply chain even more robust.

Addressing demand management, supplier integration, inventory optimisation and supply chain visibility reducing variation in performance resulting in lower operating and working capital costs is the game.

A focus should be on a Systems Thinking approach to supply chain design which will reinvent supply chain business models to improve demand visibility.

Leveraging a systems thinking approach reduces the negative impact of silos in decision making and flow of information and materials. Improvements to supply chain effectiveness from a systems based approach has yielded a 24 to 60 month visibility in demand leading to a 10 to 20% decrease in inventory in a mining related use case.

Think about answering important questions that impact profitability like -

To what extent do silos between Supply Chain and Engineering and/or Maintenance impact decision making and organisational performance?

To what extent is supply chain resilience a critical risk to organisation's profitability?

To what extent is frontline effectiveness compromised by poor integration between supply chain and maintenance?

How do silos with Supply Chain and Maintenance processes and their systems impact achieving or overachieving your KPIs?

To what extent is supply chain performance impacted by visibility of material flow?

To what extent is maintenance productivity and cost impacted by non availability of supply?

The business benefits across organisational roles can be locked in -

CFOs can address profitability, governance and risk management by improving supply chain resiliency and inventory optimisation and production asset performance. How? Reinventing supply chain business models to improve demand visibility.

Continuous Improvement Managers to improve processes and costs by improving asset reliability, supply chain resiliency and inventory optimisation. How? Reinventing supply chain business models to integrate maintaining and supply.

Supply Chain Managers to ensure availability of spares and services, inventory levels, safety and supply chain visibility. How? By improving supply chain visibility and resiliency, inventory optimisation management of repairables rotables and reinventing supply chain business models to improve demand visibility.

Engineering (Maintenance) Managers to address improvements in asset reliability and availability, maintenance costs and safety. How? By ensuring asset reliability and availability at lowest cost, without compromising productivity and integrating maintenance and supply.

For organisations that are struggling with reframing their Maintenance, Repair and Operations (MRO) supply chain business models, SAP Integrated Business Planning (IBP) and Manufacturing Intelligence solutions focus on that goal,