What would having the right spare parts and right workforce in the right place at the right time mean for your Maintenance, Repairs and Operations (MRO) process?

Asset-intensive operations continue to be under constant pressure to keep MRO inventory levels under control while maintaining or improving service levels. Achieving success is critical, as up to 50% of unscheduled downtime can be due to a lack of spare parts or stock-outs. A costly solution can be to carry extensive spare parts inventories to buffer maintenance systems which will of course lead to higher working capital costs and inventory management costs.

Asset-intensive operations continue to be under constant pressure to keep MRO inventory levels under control while maintaining or improving service levels. Achieving success is critical, as up to 50% of unscheduled downtime can be due to a lack of spare parts or stock-outs. A costly solution can be to carry extensive spare parts inventories to buffer maintenance systems which will of course lead to higher working capital costs and inventory management costs.

The right spare parts and right workforce, in the right place, at the right time

Optimise your inventory levels and increase the availability and reliability of your assets

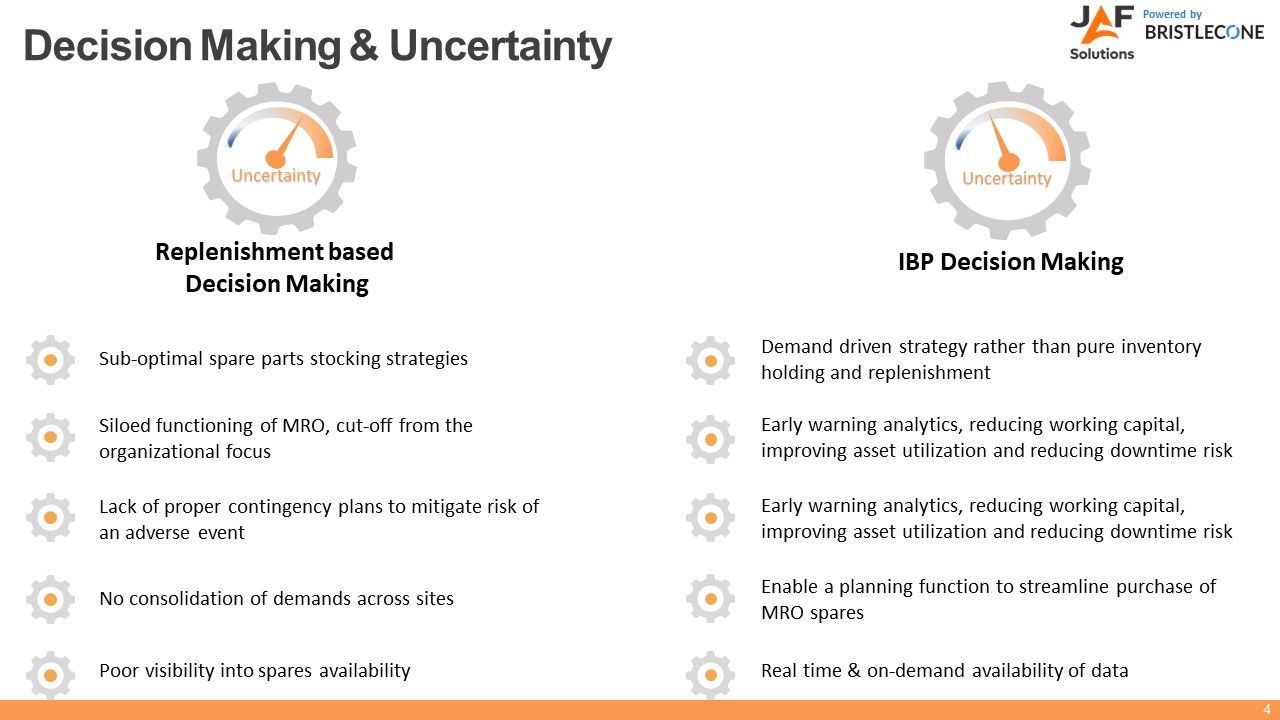

Moving away from a traditional replenishment decision-making approach to a demand-driven replenishment model can deliver improvements across the operations and lower spend but how to make it happen?

Supply Chain personnel in Asset-Intensive industries are commonly under pressure from Operations, Maintenance as well as Finance to ensure that replacement parts are available when needed to prevent unnecessary downtime and therefore loss of production. But at the same time achieving this without excessive stock, leading to working capital being tidied up in spare part inventories. These competing priorities can very quickly negatively impact top-line performance and bottom-line costs.

Reducing the uncertainty is key to making better decisions, improving asset utilisation and reducing downtime risk. Often the data and knowledge are available across operations, but it can be siloed and not easily and quickly accessible to make the informed decisions required.

So moving away from a traditional replenishment-based decision-making model to a demand-driven one can be a game changer for many roles across the operation, Maintenance, Supply Chain, Finance, IT and not forgetting the GM’s. Having a consensus plan based on the “voice of the asset”, brings demand planning, maintenance planning, inventory optimisation, and procurement closer together, and focuses on overcoming unexpected maintenance delays due to lack of spare parts availability, while optimising inventory levels.

Reducing the uncertainty is key to making better decisions, improving asset utilisation and reducing downtime risk. Often the data and knowledge are available across operations, but it can be siloed and not easily and quickly accessible to make the informed decisions required.

So moving away from a traditional replenishment-based decision-making model to a demand-driven one can be a game changer for many roles across the operation, Maintenance, Supply Chain, Finance, IT and not forgetting the GM’s. Having a consensus plan based on the “voice of the asset”, brings demand planning, maintenance planning, inventory optimisation, and procurement closer together, and focuses on overcoming unexpected maintenance delays due to lack of spare parts availability, while optimising inventory levels.

So what are some of the business benefits of decisions made using a Demand-Driven Replenishment model?

Inventory and Supply Chain Management

MRO involves managing spare parts, tools, and supplies required for maintenance and repairs. Effective inventory management ensures the availability of critical components, reducing downtime associated with waiting for replacement parts and optimising the supply chain.

Integration, removing the Silos

Regular and open communication between the supply and maintenance teams is vital. Our Solution enables data to be integrated from SAP ERP and shared regarding preventative, corrective and possible breakdown/failures maintenance along with spare parts requirements, and inventory levels. This helps in aligning the team’s requirements and demand and ensures that the right parts and resources are available when required.

Cost Reduction

Effective MRO strategies can help control costs by extending the lifespan of assets and avoiding premature replacement. Well-maintained equipment is less likely to experience major breakdowns, reducing the need for emergency repairs or expensive replacements.

Strong Predictive Analytic Capabilities

By leveraging advanced Artificial Intelligence (AI) algorithms and data analytics techniques, gain valuable insights into future trends, demand patterns, and potential risks. Make proactive decisions, optimise inventory levels, and enhance overall operational efficiency.

We have put together this 2 min short video to help with the understanding on how MRO planning can unlock business benefits across an operation and make a difference for CFOs to Maintenance Managers.

The business benefits across organisational roles

CFOs can address profitability, governance and risk management by improving supply chain resiliency and inventory optimisation and production asset performance. How? Reinventing supply chain business models to improve demand visibility.

Continuous Improvement Managers to improve processes and costs by improving asset reliability, supply chain resiliency and inventory optimisation. How? Reinventing supply chain business models to integrate maintaining and supply.

Supply Chain Managers to ensure availability of spares and services, inventory levels, safety and supply chain visibility. How? By improving supply chain visibility and resiliency, inventory optimisation management of repairables rotables and reinventing supply chain business models to improve demand visibility.

Engineering (Maintenance) Managers to address improvements in asset reliability and availability, maintenance costs and safety. How? By ensuring asset reliability and availability at lowest cost, without compromising productivity and integrating maintenance and supply.

Continuous Improvement Managers to improve processes and costs by improving asset reliability, supply chain resiliency and inventory optimisation. How? Reinventing supply chain business models to integrate maintaining and supply.

Supply Chain Managers to ensure availability of spares and services, inventory levels, safety and supply chain visibility. How? By improving supply chain visibility and resiliency, inventory optimisation management of repairables rotables and reinventing supply chain business models to improve demand visibility.

Engineering (Maintenance) Managers to address improvements in asset reliability and availability, maintenance costs and safety. How? By ensuring asset reliability and availability at lowest cost, without compromising productivity and integrating maintenance and supply.

Demand Driven strategy of inventory holding rather than replenishment models

Optimise Stock holdings and therefore optimise capital and warehouse space

Multi-Echelon Inventory Optimisation along with simulation capabilities

One holistic way to calculate your total spare requirements

Reduce the guesswork on your budgets with bottom-up maintenance cost budgeting

Summary

Having a data-driven Maintenance, Repair, and Operations (MRO) process, continuously assures that the right parts, right workforce and tools needed to keep assets operating are available during the maintenance activities. It can have a big impact on both top-line performance and bottom-line costs. It is an essential component of an overall asset management strategy that will contribute to an operation's long-term success.

With experience in both the Asset Intensive Industries and Supply Chain Management the team at JAFS can offer MRO solutions designed to tackle customers’ specific demands. We have developed a guide on packages so there is upfront visibility of the capabilities, benefits, project duration and investment an implementation requires. Contact us for more information or for our brochure.

With experience in both the Asset Intensive Industries and Supply Chain Management the team at JAFS can offer MRO solutions designed to tackle customers’ specific demands. We have developed a guide on packages so there is upfront visibility of the capabilities, benefits, project duration and investment an implementation requires. Contact us for more information or for our brochure.

Contact us to find out more

Speak to us about how our team can assist you.