- Increases productivity up to 50% (source IDC).

- Creates immediate access to decision-critical data, enabling better decison making.

- Reduces storage space cost by up to 80%.

- Traceability and compliance to mandated regulations.

- Possible 75% reduction in overtime.

- 90% reduction in labeling errors.

- More sustainable approach.

- Easier to scale production.

Three main takeaways

It's a journey and not a single sprint

By digitising your processes you will also find ways to optomise and update your processes, take the time to review processes as part of the project. There will be many benefits that can be baked into your processes once you are on the road.

The reality and costs of paper systems

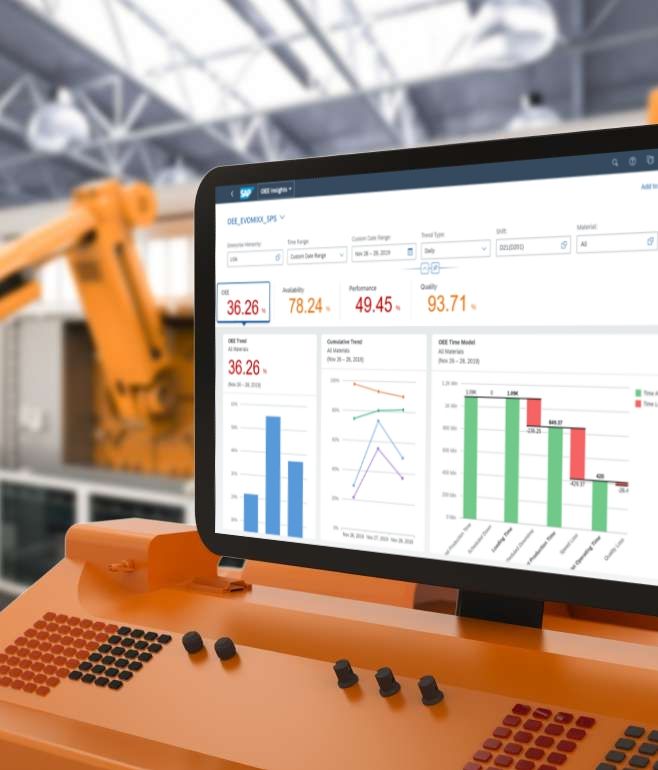

Choosing the right tool

The choice of the right tool to go paperless is critical. consider integration capabilities to your ERP as well as the shopfloor, how configurable, usability, and mobility ability.

Improved Decision Making

One of the major advantages of digitisation is the reduction of decision latency which currently exists in all paper-based operations. Digitisation allows data to be recorded and reported almost instantly; decisions can be taken much faster, and with more confidence, preventing losses/delays within the production processes.

Have a more sustainable approach

Everyone is talking about sustainability, by going paperless you would be not only making your processes more sustainable and efficient, but also the environment by reducing paper consumption and waste.

Replace manual data collections and paper work instructions

Instead of relying on paper-based instructions, digitized manufacturing provides electronic work instructions. This ensures that operators have access to the latest and most accurate information, reducing the likelihood of errors caused by outdated manuals.

Reduce the effort of compliance management

Paper-based records are generally not secure enough and the data accuracy can be questioned. Important documents may get destroyed due to various reasons, as paper is perishable and prone to damage depending on the conditions of storage.

Documents, especially compliance-related ones, if not stored digitally may be lost, leading to serious quality-related claims and non-compliance-related actions from regulatory authorities.

Modern MES also often have a digital sign off ability, this can include a dual sign off as well which is required for the Pharmaceutical Industry.

Summary

The extent to which paper is replaced will depend on several aspects, the capability of the system, the ability to adopt new processes and systems and the level of equipment and sensors within your plant.