The manufacturing sector is currently facing a critical juncture.

The manufacturing sector is currently facing a critical juncture.

On one hand, there is an increasing demand for manufactured goods, signalling growth and prosperity. On the other hand, concerns around a potentially decreased labour force are casting a shadow over this positive outlook. The juxtaposition of these two forces necessitates a strategic and innovative approach to manufacturing, ensuring that companies can meet demand without being hamstrung by labour shortages. In this blog, we explore how manufacturers can navigate these challenges through strategic innovation and operational agility.

Embracing Efficiency and Agility

Manufacturing faces a pressing need for efficiency and agility to overcome current challenges. This requires a critical analysis and streamlining of the entire production workflow. Every stage, from sourcing materials to delivering final products, must be examined for potential enhancements.

It's not enough for companies to consider efficiency as an industry catchphrase; it must be an integral part of their operational ethos. By pinpointing and refining processes where time, effort, and resources are excessive, companies can ensure they're not only meeting but exceeding modern manufacturing demands.

Bridging the Skills Gap

Addressing labour shortages in manufacturing goes beyond hiring; it involves closing the prevalent skills gap. Today's industries aren't just grappling with a scarcity of workers, but with a deficit in expertise regarding emergent manufacturing technologies and practices. To counter this, a commitment to technical training and continuous upskilling is vital.

Manufacturers must invest in educational initiatives that bring their workforce up to speed with the latest advancements, from digital fabrication techniques to smart automation and data analytics. Such training programs are indispensable in ensuring employees are adept and confident in their roles, which in turn drives productivity. Furthermore, a well-trained employee is typically a more satisfied and engaged one, leading to lower turnover rates.

By focusing on nurturing a knowledgeable and versatile workforce through ongoing education, companies can foster a work environment where innovation thrives.

Automation and Robotics: The New Workforce

In the face of workforce shortages, automation and robotics emerge as vital allies in manufacturing. These innovative technologies stand in for human labour, elevating production with unmatched precision and steadfast efficiency.

The introduction of intelligent automation systems like SAP Digital Manufacturing allows manufacturers to sustain high-performance operations, even with fewer staff members. SAP Digital Manufacturing streamlines production processes, provides real-time data and insights and empowers employees with the tools and information they need to excel at their tasks. When employees interact with state-of-the-art technology and systems that make their work more efficient and rewarding, they feel a greater sense of accomplishment and engagement. This shift also mitigates the immediate challenges of understaffing and is beneficial in propelling production processes toward reliability and excellence.

Leveraging Advanced Manufacturing Technologies

The integration of cutting-edge manufacturing technologies is transforming the industry. 3D printing unlocks the potential for intricate and bespoke product designs, while the Internet of Things (IoT) connects and streamlines various components of the manufacturing process for enhanced monitoring and efficiency. Artificial Intelligence (AI) further augments this AI-enabled visual inspection and anomaly detection.

The integration of cutting-edge manufacturing technologies is transforming the industry. 3D printing unlocks the potential for intricate and bespoke product designs, while the Internet of Things (IoT) connects and streamlines various components of the manufacturing process for enhanced monitoring and efficiency. Artificial Intelligence (AI) further augments this AI-enabled visual inspection and anomaly detection.

Such advancements not only boost the speed and volume of manufacturing but also elevate the quality and customisation of the output. They enable manufacturers to respond swiftly to changing consumer preferences and complex design requirements. The agile nature of these technologies means that production can pivot quickly, scaling up or down as needed to match market demand. This adaptability ensures that manufacturers can remain competitive and resilient, even in fluctuating economic climates.

The Power of Cross-Training

Cross-training stands as a strategic pillar in fortifying the manufacturing workforce against the backdrop of labour shortages. This approach involves the comprehensive education of employees across a spectrum of skills and functions within the organisation. By cultivating a workforce proficient in a variety of roles, manufacturers can create a pool of talent capable of stepping into different positions as demands fluctuate.

This multi-disciplinary training equips teams to handle diverse challenges and seamlessly adapt to shifting production needs. It not only enhances the operational flexibility of the company but also fosters a more collaborative and innovative workplace culture. Employees gain a broader understanding of the business, which can lead to more efficient practices and a more engaged workforce.

Exploring Outsourcing and Partnerships

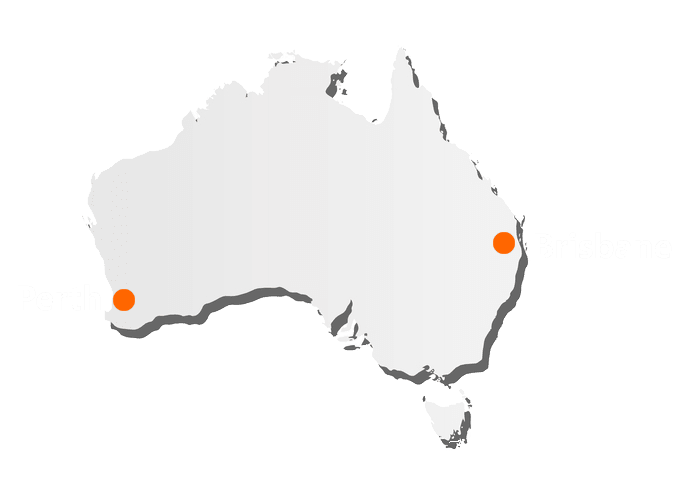

To meet rising demand, manufacturers may find solutions beyond their facilities. Outsourcing selected operations or forging strategic alliances offers an immediate expansion of capacity and capabilities. This approach allows companies to leverage external expertise and technology without the permanence of enlarging their in-house team.

By tapping into the strengths of partners and vendors, manufacturers can nimbly adjust to market demands and maintain a competitive edge.

Fostering Employee Engagement and Retention

Cultivating a dedicated and involved employee base is essential for any manufacturing enterprise aiming to thrive. When workers are engaged, they're more likely to remain with the company, curbing the frequency of turnover and minimising the expenses related to hiring and onboarding new staff. Active engagement strategies, such as acknowledging employee achievements, providing clear pathways for career progression, and fostering a supportive and inclusive workplace environment are critical.

Cultivating a dedicated and involved employee base is essential for any manufacturing enterprise aiming to thrive. When workers are engaged, they're more likely to remain with the company, curbing the frequency of turnover and minimising the expenses related to hiring and onboarding new staff. Active engagement strategies, such as acknowledging employee achievements, providing clear pathways for career progression, and fostering a supportive and inclusive workplace environment are critical.

Digital Manufacturing solutions assist with employee engagement and retention in two keys ways. With the next generation of employees who are tech savvy coming into the workforce solutions like SAP Digital Manufacturing fosters employee engagement with a consistent user interface across roles which is quick and easy to use providing a flexible workforce across organisational roles. With more repetitive tasks continuing to be automated this frees up time for more interesting and higher value activities by employees which contributes to improved workforce retention.

Summary

These efforts lead to a workforce that not only feels valued and engaged but is also aligned with the company's goals, driving performance and innovation. Employees who see a future for themselves within the organisation will invest more deeply in their work, resulting in higher productivity and better-quality products.

The challenges posed by a potential decrease in the labour force, combined with increased demand, require manufacturers to be more strategic and innovative than ever. By embracing a mix of technological advancements, process optimisations, and workforce development strategies, manufacturers can not only survive but thrive. The future of manufacturing depends on the ability to adapt, innovate, and engage, turning potential obstacles into opportunities for growth and success.