Just five years ago, the majority of global supply chain managers were primarily concerned with enhancing efficiency through the just-in-time model, while the average person on the street remained largely unaware of the intricacies of supply chains and their significance.

Just five years ago, the majority of global supply chain managers were primarily concerned with enhancing efficiency through the just-in-time model, while the average person on the street remained largely unaware of the intricacies of supply chains and their significance.

However, the pandemic dramatically altered this landscape. Today, both business leaders and consumers have come to appreciate that a single event occurring on the far side of the globe can disrupt operations and result in shortages of essential goods. As we look ahead this year, it is evident that the turbulence initiated in 2023 is far from subsiding.

To combat this, the supply chain arena is undergoing a profound transformation driven by cutting-edge technologies, including generative AI, data analytics, automation, machine learning, the Internet of Things (IoT), blockchain and more. The emergence of the 'smart' supply chain is poised to redefine the new standard.

Given these developments, what key priorities should leaders be focusing on as they strive to perform a digital transformation and establish a sustainable supply chain in the upcoming year?

Embracing the Future of Supply Chain Management

Enabled by technological advancements, supply chain management is changing for the better. This evolution empowers organisations to respond swiftly to daily demands, proactively tackle problem-solving, minimise errors and inefficiencies, and bolster visibility, transparency, and traceability. Crucially, it enhances resilience against potential future supply chain disruptions.

Trend 1: The Role of Generative AI in Operations

Generative AI (GenAI) is set to transform the supply chain management, logistics and procurement. This advanced technology surpasses its forerunners by enabling algorithms to analyse extensive datasets, breaking through former constraints and adeptly handling a myriad of variables. The distinct feature of GenAI lies in its capacity to learn and self-optimise within a company's specific supply chain environment, thereby continuously enhancing its analytical prowess.

GenAI presents a wide range of possible uses. It can ensure adherence to procurement and regulatory standards, optimise manufacturing processes, and improve virtual logistics coordination through effective virtual assistants. Nonetheless, embedding AI into organisational frameworks demands a comprehensive strategy. It's crucial to avoid fragmenting efforts into separate, uncoordinated AI initiatives. A thorough strategic reassessment and reengineering of fundamental business procedures are essential to fully leverage AI's capabilities.

GenAI presents a wide range of possible uses. It can ensure adherence to procurement and regulatory standards, optimise manufacturing processes, and improve virtual logistics coordination through effective virtual assistants. Nonetheless, embedding AI into organisational frameworks demands a comprehensive strategy. It's crucial to avoid fragmenting efforts into separate, uncoordinated AI initiatives. A thorough strategic reassessment and reengineering of fundamental business procedures are essential to fully leverage AI's capabilities.

SAP's Integrated Business Planning for Supply Chain uses advanced machine learning to enhance demand forecasts with real-time sales data, while also improving planning with self-correcting data and lead time predictions. Upcoming generative AI capabilities include:

- Improved human-machine interaction: The new generative assistant, Joule, will enable natural user-system communication, efficiently answering complex queries by integrating diverse data across SAP's cloud enterprise network.

- Creative assistance: Generative AI will collaborate with professionals in ideating and refining new product designs within the SAP Enterprise Product Development cycle.

- Transforming unstructured data: It will swiftly match unstructured data, like cargo lists, with structured system data, leveraging technologies like OCR for efficient processing.

Trend 2: Empowering AI-Driven No-Touch/Low-Touch Planning

Organisations are increasingly prioritising resilience, ESG goals and dealing with the complexities of growing operations, leading to immense stress on supply chain planning. Traditional planning methods are lagging behind the demands of the global multi-tier landscape. Consequently, only a few companies can perform thorough scenario analysis to understand the financial impact of major decisions.

AI-driven Sales and Operational Planning (S&OP) and Integrated Business Planning (IBP) are emerging to link supply chain planning with execution effectively. These technologies aim to reduce manual work in the entire planning process, using advanced analytics for deep inquiries with minimal human input. AI's potential lies in analysing large datasets, identifying anomalies, discovering patterns causing disruptions, and quickly offering solutions. Today’s SAP IBP Offering is a good example of a tool with these technologies already embedded within the product.

Technologically, these tools are akin to a control tower or a more sophisticated cognitive decision centre, featuring digital twin technology. Such advancements promise better predictability, increased gross margins, and freeing up resources for more value-driven tasks.

Trend 3: The Power of Data

In today's supply chain management, the central challenge lies in handling the vast amount of data generated daily across various systems. The rise of digital technologies, IoT devices, and advanced tracking systems has led to an increase in data silos and disconnected datasets within organisations, causing issues like data duplication and misinterpretation. This complicates the development of a comprehensive understanding of the supply chain.

In today's supply chain management, the central challenge lies in handling the vast amount of data generated daily across various systems. The rise of digital technologies, IoT devices, and advanced tracking systems has led to an increase in data silos and disconnected datasets within organisations, causing issues like data duplication and misinterpretation. This complicates the development of a comprehensive understanding of the supply chain.

Consequently, the importance of data aspects such as availability, quality, cadence and consistency cannot be overstated. Supply chain professionals need to adeptly manage their data to make well-informed decisions and enhance operational efficiency.

To tackle this challenge in 2024, organisations are advised to:

- Emphasise crucial data elements like availability, quality, reliability, cadence and consistency, acknowledging their role in informed decision-making and building resilience against disruptions.

- Recognise data management as a continuous process rather than a one-off task.

- Embrace a flexible, iterative approach to data management.

- Create a data-focused roadmap that aligns data initiatives with specific goals, including cost reduction, increased efficiency, customer satisfaction, and innovation.

Trend 4: Expanding Supply Chain Visibility Beyond Tiers 1 and 2

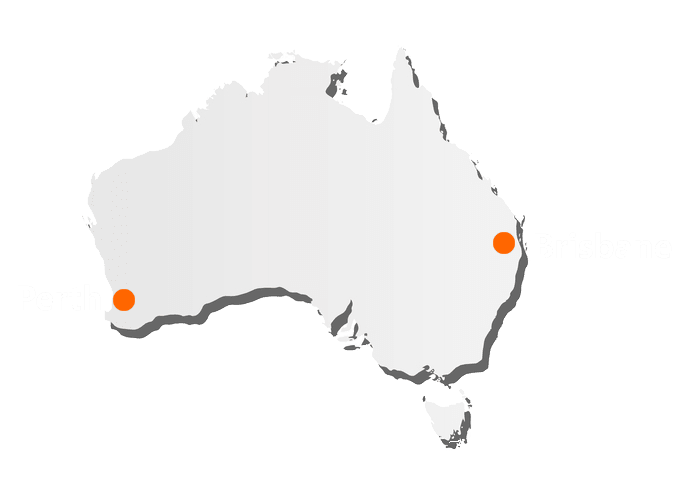

Insufficient insight into the various levels of a supply chain presents major challenges for companies, affecting compliance with regulations and the management of supply chain risks. Expanding this visibility past the first tier allows businesses to examine their broader supply network in greater depth. This results in valuable knowledge about fundamental causes, the identification of distant risks, and progress in Environmental, Social, and Governance (ESG) goals due to improved traceability.

Tools such as control towers and digital twins are instrumental in uncovering vital relationships with sub-tier suppliers, pointing out common suppliers and factory locations in lower tiers, and providing a comprehensive view of the supply chain's extent. When used effectively, these tools bolster the resilience of the supply chain.

In 2024, the focus is on adopting data-driven strategies and technology to improve collaboration and expand visibility across product flows, ensuring a comprehensive grasp of the supply chain. Key initiatives include forming cross-functional teams for a holistic view on essential use cases, the necessary level of visibility, and identifying downstream issues. Collaborating with other organisations aiming to enhance their supply chain visibility and control towers is also vital, as it provides access to extensive data and insights. Furthermore, embedding Environmental, Social, and Governance (ESG) considerations into technology is crucial for refining procurement decisions and performance management, as well as integrating ESG metrics into supplier evaluations and scorecards.

Trend 5: Embracing ESG and Scope 3 Emissions

Historically, the focus of businesses has been on monitoring their direct emissions (Scope 1) and emissions from purchased electricity (Scope 2). However, there's a growing trend towards scrutinising Scope 3 emissions, which include emissions from the entire value chain. What was once a voluntary practice is now increasingly becoming a legal requirement in many countries to collect and report on Scope 3 emissions data.

Historically, the focus of businesses has been on monitoring their direct emissions (Scope 1) and emissions from purchased electricity (Scope 2). However, there's a growing trend towards scrutinising Scope 3 emissions, which include emissions from the entire value chain. What was once a voluntary practice is now increasingly becoming a legal requirement in many countries to collect and report on Scope 3 emissions data.

Establishing a solid baseline for emissions is essential for tracking progress and setting ambitious reduction targets. While measuring Scope 1 and 2 emissions is relatively simple, the task becomes more complex when it expands to include the entire supply chain, as is the case with Scope 3 emissions.

For effective carbon emission reduction, companies need to gather primary emissions data from their suppliers. They are shifting towards hybrid carbon accounting methods to accurately assess Scope 3 emissions. Digital platforms are emerging as centralised systems where suppliers can report their emissions data, making it easier to integrate this information into a company's sustainability reports.

SAP has committed to achieve net-zero along its value chain in line with a 1.5°C future in 2030 – 20 years earlier than originally targeted, it’s product suite already has sustainability and emission tracking embedded with it, this capability is been added to with future releases.

Summary

Ongoing disruptions and the market landscape shaped by the pandemic have unveiled three critical deficiencies within supply chains: a lack of visibility, transparency, and traceability.

These shortcomings underscore the significance of the top supply chain trends.

The foremost priorities revolve around technology adoption, specifically the digital supply chain, big data and analytics, and AI and machine learning. Organisations are increasingly focused on incorporating these technologies to bridge the gaps laid bare by the pandemic.