A lot has happened since COVID-19 first disrupted the world order nearly three years ago, with other events such as the blocking of the Suez Canal, the ongoing war in Ukraine, now rising inflation, and severe weather events—all happening on top of the ongoing pandemic and associated challenges Extreme volatility is a new reality worldwide, a lot of work was done by manufacturers, however, now is the time to reflect on your efforts and ensure that you are now best placed for this constant Disruption.

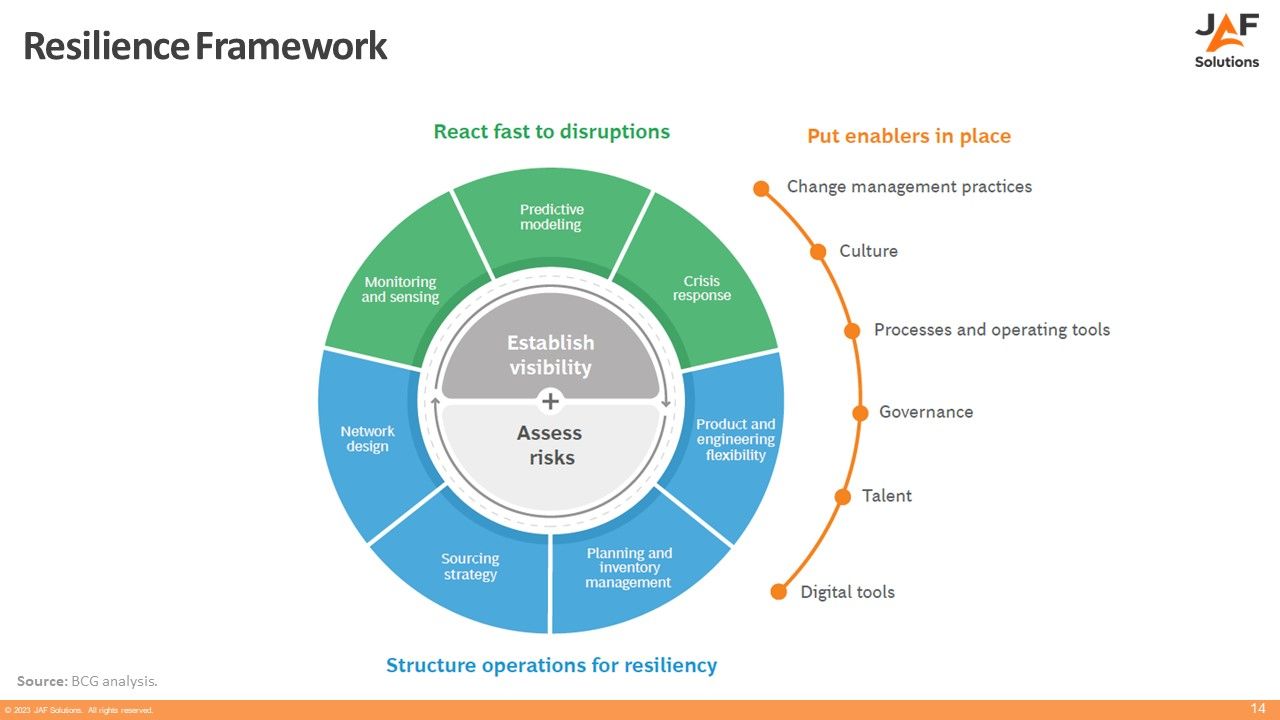

Adoption of a Resilience Framework such as the one outlined below is key, visibility and tools to enable this visibility and "what if" are critical to success and helping to ensure better decision-making can take place,

Adoption of a Resilience Framework such as the one outlined below is key, visibility and tools to enable this visibility and "what if" are critical to success and helping to ensure better decision-making can take place,

Ability to Absorb

“Bottom of wheel” activities address the ability to absorb disruptions with:

- network design,

- sourcing strategy,

- inventory and planning, and

- flexible products and engineering.

Ability to Recover

“Top of wheel” activities address the ability to recover from disruptions:

- monitor and sense: enabling the ability to see disruption on the horizon,

- predictive modelling: employing “what if” scenarios, and

- crisis response: having a plan for when disruptions occur.

- Top-of-wheel agility indicates your organization’s ability to get in front of events faster than your competitors.

Enabling better decision-making for proactive improvements

Tools Such as SAP IBP can enable this visibility and "what if" scenarios with monitoring/sensing along with Predictive modelling and this help to enable better decision-making.

Key Points

Keep the following in mind when assessing your organisation’s risk readiness and planning improvements to your operational resilience.

- Think of investing in resilience as a form of insurance that can result not only in mitigating loss but in gaining market share.

- Put as much effort or ideally more into “fire prevention” (proactive design improvements) as “firefighting” (reactive capabilities) once they reach a point in their operational maturity where this makes sense.

- Now is the time to focus on supplier relationship management and becoming the customer of choice for your key suppliers. However, don’t fall into the trap of relying on only one source for key supply chain inputs.

Contact us to find out more

Speak to us about how our Advisory Practice team can assist you, or about how tools such as SAP IBP can assist you as an enabler.