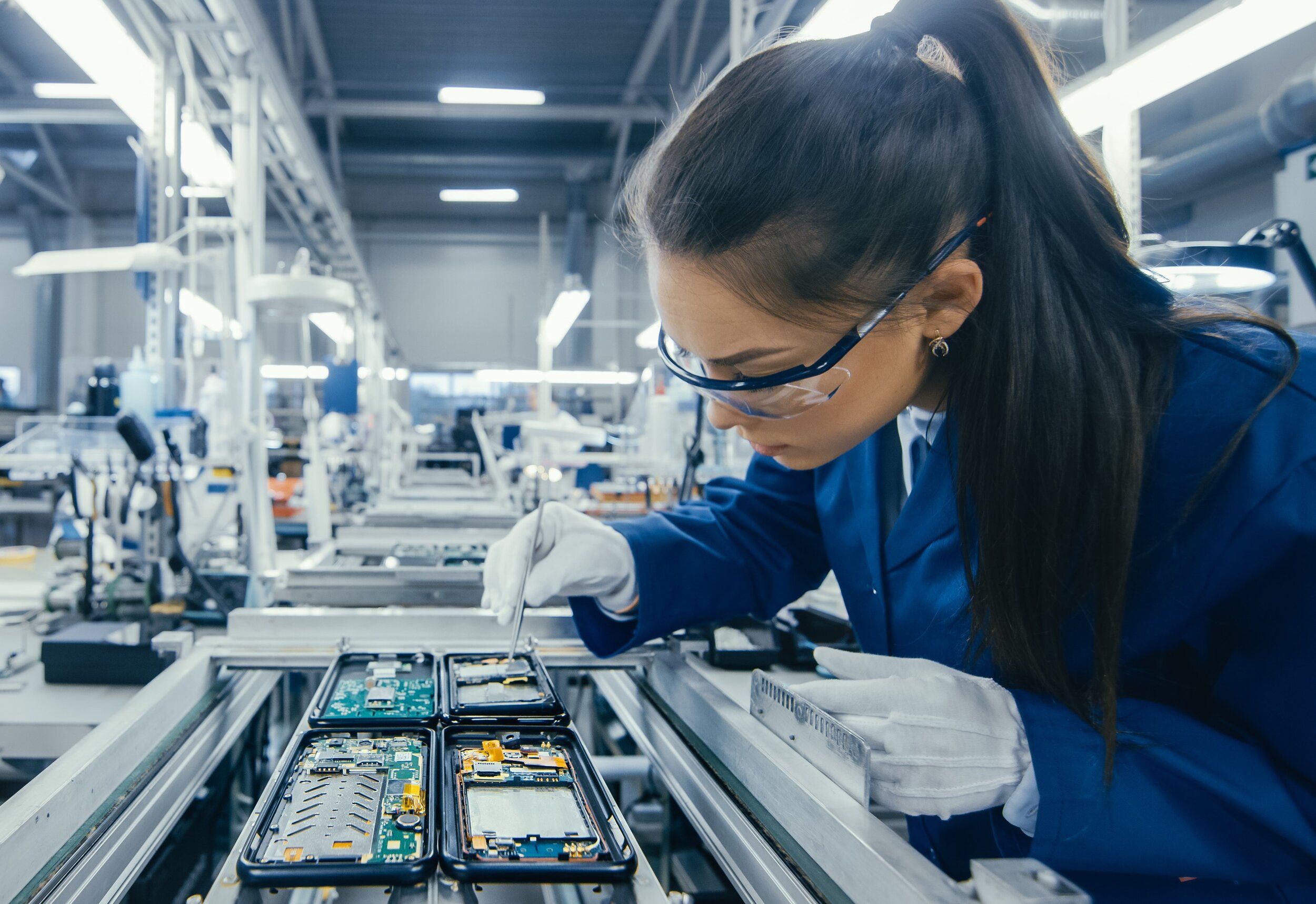

Managing your manufacturing operations can be a challenge and feel like a never-ending juggling act. SAP Digital Manufacturing (DM) is a Manufacturing Operations Management (MOM) system that can turn business challenges into competitive advantages. Modern manufacturers' who are looking to streamline operations, eliminate non-value-added activities, and improve overall productivity are integrating lean manufacturing principles like just-in-time (JIT) production, waste reduction, and visual management into manufacturing operations.

One of the benefits of SAP DM as your MOM is the seamless integration with other systems like SAP Enterprise Resource Planning (ERP), Quality Management Systems (QMS), and Supply Chain Management (SCM) allowing for seamless data exchange and collaboration between different functions, improving overall operational efficiency and in turn driving improvement in Overall Equipment Effectiveness (OEE).

Manufacturing Operations Management

OEE is probably one of the most used key performance indicators in manufacturing to measure the efficiency of production processes, it's calculated by multiplying the availability, performance, and quality of equipment. The goal of manufacturing operations management (MOM) is to optimise production processes and increase OEE by reducing downtime, increasing equipment performance, and improving quality.

Optimising production processes with MOM involves the use of technology and best practices to manage the end-to-end manufacturing process, like planning, scheduling, execution, monitoring, and analysis. Providing real-time visibility into production processes, enabling manufacturers to identify and address issues before they impact production and profit. Additional benefits of MOM solutions is that they typically integrate with enterprise resource planning (ERP) systems and shop floor equipment with the aim to streamline operations and improve overall efficiency.

So how can MOM improve your OEE?

Reduce Unplanned Downtime

Improve Quality

Monitor OEE

Improve Equipment Performance

Optimise Production Planning